Why a Bike Engine Cranks but Does Not Start

If a bike engine cranks but does not start, the starter system is working but combustion is failing. This article explains real technical causes—such as weak ignition under load, poor fuel atomization, sensor faults, or low compression—and how to identify them correctly.

The real question behind this

When a bike cranks but does not start, the engine is already doing part of its job.

The confusion comes from not knowing why rotation is happening without combustion.

This situation rules out some problems and points directly to others.

Understanding this difference is key to finding the real fault.

What this means

A bike engine that cranks but does not start indicates that the starter system is working, but combustion is failing.

This narrows the problem to three technical areas:

- Ignition spark is weak, mistimed, or absent

- Fuel delivery or atomization is incorrect

- Compression or valve timing is insufficient

Unlike a dead starter or battery failure, this condition points to functional but incomplete systems, which require targeted diagnosis.

$750 Amazon Gift Card

Some users qualify for a $750 Amazon gift card. You can check if you qualify.

Why this matters today

Modern motorcycles rely on electronic ignition, sensors, and precise fuel delivery. Small deviations in voltage, fuel pressure, or sensor signals can completely prevent starting.

At the same time, ethanol-blended fuels, infrequent riding, and compact engine designs increase sensitivity to contamination and electrical resistance. What has changed is complexity. What has not changed is that combustion must occur cleanly and at the right moment.

Misdiagnosis leads to repeated failures and unnecessary part replacement.

How this works in practice

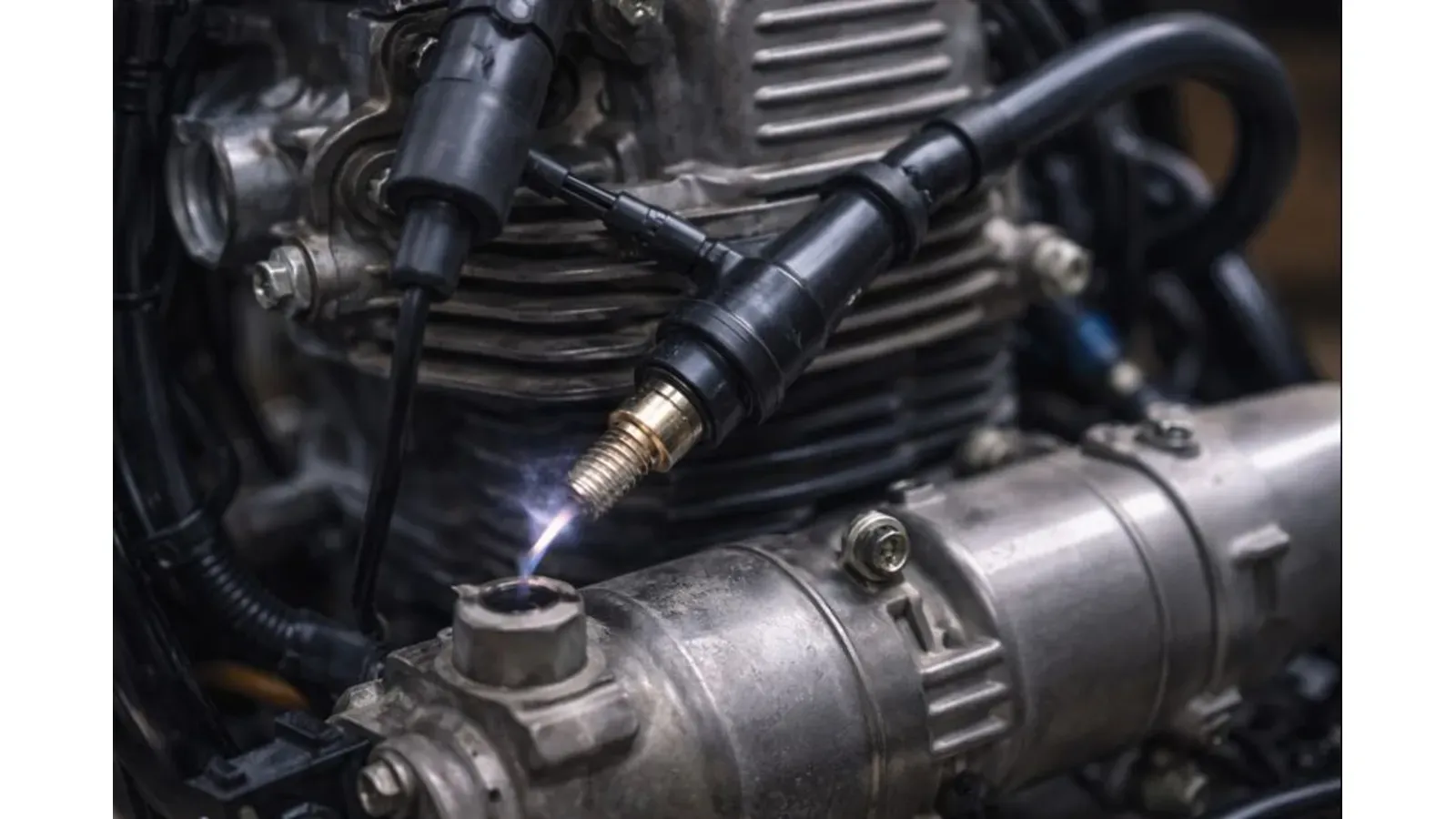

Ignition system failure under load

A spark plug may produce a visible spark outside the engine but fail under compression. Weak ignition coils, degraded plug caps, or high-resistance wiring reduce spark energy exactly when it is most needed.

Technical fact: Spark voltage demand increases significantly under cylinder pressure.

Takeaway: A visible spark does not guarantee ignition inside the engine.

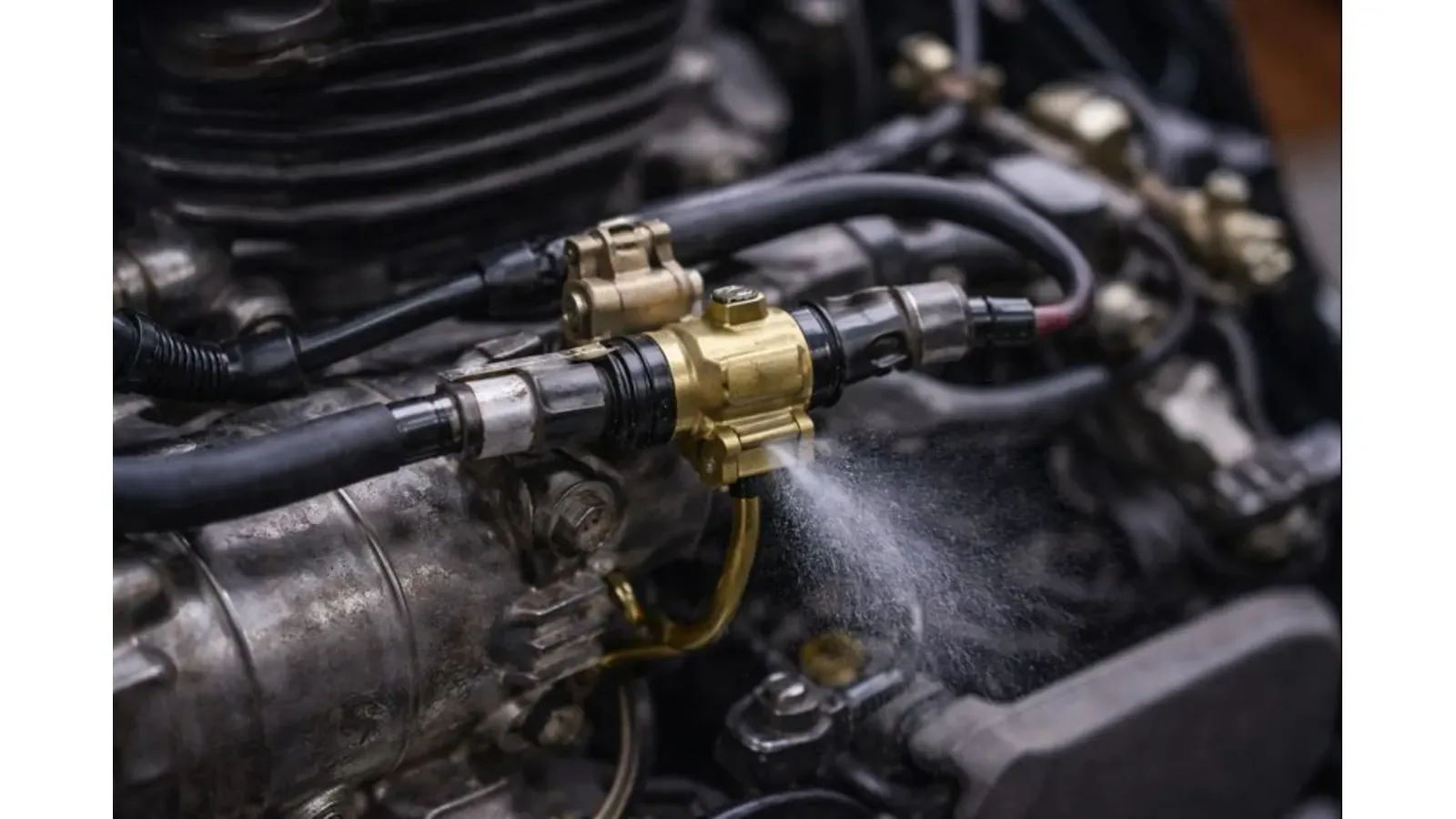

Fuel delivery without proper atomization

Fuel may reach the cylinder but fail to atomize correctly. Clogged injectors, stuck carburetor floats, or low fuel pressure cause wet plugs or dry combustion chambers.

Technical fact: Liquid fuel droplets do not burn efficiently without proper atomization.

Takeaway: Fuel presence alone does not equal combustible mixture.

Incorrect sensor input (fuel-injected bikes)

Faulty crank position sensors, throttle position sensors, or temperature sensors can prevent ECU-triggered injection or ignition timing. The engine cranks, but timing logic is incorrect.

Technical fact: ECUs rely on synchronized sensor signals to trigger ignition events.

Takeaway: Sensor faults can cause silent no-start conditions.

Compression loss from valve or ring wear

Low compression caused by worn piston rings, valve leakage, or incorrect valve clearance prevents pressure buildup. The engine turns freely but cannot sustain combustion.

Technical fact: Combustion efficiency depends on minimum compression thresholds.

Takeaway: Compression loss causes repeated cranking with no ignition.

Flooding or fuel saturation

Repeated starting attempts can flood the cylinder, washing oil from cylinder walls and lowering compression temporarily.

Takeaway: Over-cranking can worsen an already marginal condition.

Real-world scenarios or examples

A rider reports strong cranking and fuel smell but no start. Inspection reveals a failing ignition coil that produces spark only at low pressure.

Another bike starts only after long rest periods. Diagnosis shows injector clogging that worsens as fuel evaporates and deposits form.

These cases show how specific technical faults create predictable no-start patterns.

Quick Under Standing Summary

If a bike engine cranks but does not start, the starter system is functional, but combustion is failing. Common technical causes include weak ignition under compression, poor fuel atomization, faulty sensors, or low compression. Identifying whether spark, fuel delivery, or compression is failing under real conditions is essential for accurate repair.

Common mistakes to avoid

A frequent mistake is replacing batteries or spark plugs without testing under load. Another is assuming fuel problems without checking ignition timing or sensor data. Ignoring compression testing often leads to repeated unsuccessful repairs.

Comparisons / alternatives

| Observation | Technical implication |

|---|---|

| Cranks fast, no ignition | Spark or fuel timing issue |

| Fuel smell, wet plug | Flooding or weak spark |

| Dry plug after cranking | Fuel delivery failure |

| Starts only when cold | Sensor or mixture error |

This comparison reflects real diagnostic reasoning.

User real review / expert perspective

@HeroMotoCorp I am very unhappy with my Hero motorcycle. The new motorcycle has developed a problem with the self-start system, and the authorized Hero workshop is not providing any solution and is treating me poorly.

— कमलेश मिश्रा (@kamlesh65able) December 22, 2025

Suresh Patel, daily commuter: “My bike cranked fine but wouldn’t start. The issue was a weak ignition coil that failed only under compression.”

Expert – Motorcycle technician Ramesh Kulkarni: “Most crank–no-start cases are ignition or injector-related, not mechanical failure.”

Q. Ever kickstart a motorcycle? If so, do you remember the year, make and model?

— 𝙏𝙤𝙩𝙖𝙡 𝙈𝙤𝙩𝙤𝙧𝙘𝙮𝙘𝙡𝙚™ 🏍 ᵉˢᵗ ¹⁹⁹⁹ (@TotalMotorcycle) July 21, 2025

Video: Now that's a proper way to start up a big 'ol bike, pretty awesome.#motorcycle #motorbike #Kickstarter #Bike #BIKER #harleydavidson #kawasaki #SUZUKI #YAMAHA #indianmotorcycle #BMWmotorrad pic.twitter.com/K0SIxFb6U6

Future trends / predictions

Future motorcycles will integrate real-time fault detection and onboard diagnostics. However, ignition energy delivery and fuel quality will remain critical failure points. Basic combustion principles will not change.

Final answer / solution

When a bike cranks but does not start, the real solution is to identify which combustion requirement fails under load—spark strength, fuel atomization, sensor timing, or compression. Testing these systems under real operating conditions solves the problem reliably and prevents repeat failure.

$750 Cash App Gift Card

A $750 Cash App gift card may be available to select users. Checking eligibility is quick. You can check if you’re one of them.

FAQs

Can a bike crank with a bad ignition coil?

Yes. The starter circuit is independent of ignition output.

Does fuel smell mean fuel delivery is fine?

No. It may indicate flooding or poor atomization.

Should compression be tested early?

Yes, especially if spark and fuel are confirmed.

Can sensors prevent starting without error codes?

Yes. Some failures remain within ECU tolerance limits.

Conclusion

A cranking bike that does not start is signaling a specific combustion failure, not a general problem. Understanding how ignition, fuel, sensors, and compression interact leads directly to the real technical cause and a lasting fix.